Newly Developed Two Types of Grinding Wheels for Si and SiC Wafers

DISCO CORPORATION, a semiconductor manufacturing equipment manufacturer (Head Office: Ota-ku, Tokyo; President: Kazuma Sekiya), has developed two types of grinding wheels, the Poligrind PW21 Series for Si wafers including memory ICs and logic ICs, and the GFSC Series for SiC wafers. Sales of both products have already begun, and they will be exhibited at SEMICON Japan 2022 (to be held from December 14th to 16th at Tokyo Big Sight).

Poligrind PW21 Series: Grinding Wheels for Si Wafer Thinning

Developmental Background

The markets for logic ICs such as CPU and GPU, and memory ICs such as NAND flash memory and DRAM are forecast to continue to grow in the future with a focus on investment in data centers. These semiconductor devices achieve a high degree of integration as the die are laminated after thinning and singulation. In wafer thinning for high-end products, as they are made ultrathin, polishing is performed after grinding to remove the damage from the grinding process. However, in wafer thinning for mid-range products, a medium level of thinning is performed using only the grinding process. For this processing application, we have been providing the PW06 Series, Poligrind wheels that cause less grinding damage, and now DISCO has newly developed its successor product, the PW21 Series.

Features

Improved Throughput and Enhanced Die Strength

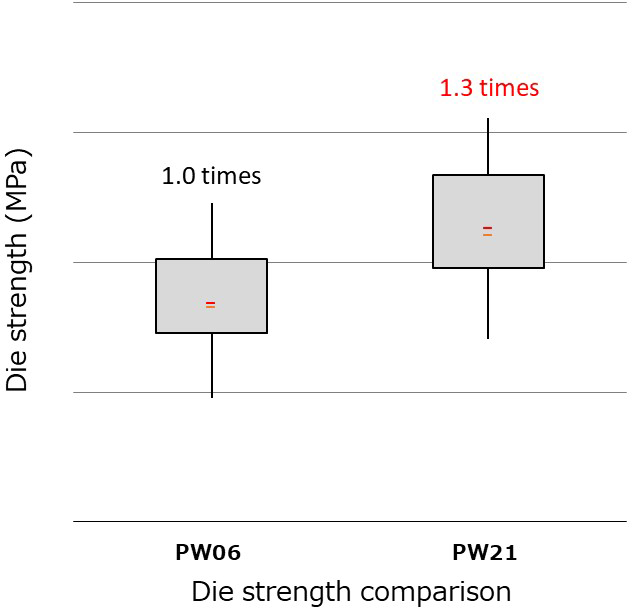

The PW21 Series can achieve 1.3 times the die strength compared to the conventional series even when the feed rate is increased to be 1.5 times faster. It can also improve wheel life.

GFSC Series: Grinding wheels for SiC Wafers

Developmental Background

Carbon neutrality is now a pressing social issue, and energy saving is required in every situation. In response to this issue, conversion between alternate and direct current, voltage, and frequency is necessary to achieve high-efficiency power control, and power semiconductors are utilized for this. In particular, energy saving directly affects the cruising range of EVs (electric vehicles), and thus demands for high-efficiency power semiconductors are increasing.

Compared to Si (silicon), which has been used thus far, SiC (silicon carbide) enables high-temperature operation and has a low resistivity. Therefore, it is rapidly being adopted in the manufacturing of power semiconductors. SiC is physically tough, and is also the second hardest crystal next to diamond, making high quality, stable processing difficult. Therefore in order to process SiC, there were needs for grinding wheels that have a high grinding performance.

Features

DISCO has been developing grinding wheels for SiC since 2006, when Φ4-inch wafers were mainstream, and the GFSC Series is the fourth generation of grinding wheels for SiC starting from the first generation in 2008.

The GFSC Series has a lineup that covers a wide range of SiC semiconductor manufacturing processes from rough/finish grinding for wafer manufacturing up to rough/finish grinding for device manufacturing. With this series, stable processing due to a reduced grinding load, improved processing quality, and improved wheel life can be achieved in all processes.

Sales Schedule of Both Products

Both products are currently available. Please contact a DISCO sales representative for more details.

About DISCO

DISCO is a semiconductor equipment manufacturer that provides precision processing equipment, including dicing saws and grinders, and precision processing tools (blades and wheels) used for manufacturing semiconductors and electronic components. In addition to these products, as a result of pursuing optimal processing results for customers through the provision of the technology used with the equipment and tools, DISCO products and processing technologies have been widely adopted by device manufacturers and semiconductor subcontractors both domestically and internationally. For details, please visit the DISCO website at www.disco.co.jp.

Contact

Please feel free to contact us with any questions or inquiries.