Newly Developed DAD3351, Semi-Automatic Dicing Saw for Φ200 mm

Completion of Model Change for All Semi-Automatic Dicing Saws

DISCO CORPORATION (Head Office: Ota-ku in Tokyo, President: Kazuma Sekiya), a semiconductor manufacturing equipment manufacturer, has developed DAD3351, a model with reduced processing time and footprint. Additionally, DAD3361 and DAD3431 have also been developed. Along with the development of these three models, DISCO has also completed a model change for all nine semi-automatic dicing saw models, with improved productivity and communication support in all models.

Background of Model Change for All Semi-Automatic Dicing Saws

For mass production, multiple units must be installed and simultaneously operated in parallel due to the time needed to process difficult-to-cut materials, such as glass and ceramics used for sensors and passive components. Thus, many production sites adopt manual dicing saws with simple functions, and a small group of operators control them. However, communication functions were limited in existing models, which made it difficult to control them centrally. For this reason, there was demand for communication support that would enable timely control of multiple dicing saws. Given this background, a model change was carried out for all nine existing semi-automatic dicing saw models.

Product Features of DAD3351

The existing semi-automatic dicing saw DAD3350 is a best-selling model that flexibly supports a wide range of workpieces and has been delivered to many companies around the world. The newly developed DAD3351 has inherited the features of DAD3350, with a high-rigidity bridge-type frame for the spindle axis, which can withstand high-load processing, and high extensibility to support various options and user-specified specifications. Accompanying the model change (details below) carried out for all nine semi-automatic dicing saws, the following features have been improved.

Approx. 5% Reduction in Processing Time

- By increasing the axis speed through an improvement in motor performance and by optimizing the parameters, the processing time has been reduced by 5% (compared to DAD3350).

Comparison of Highest Return Speed of Each Axis

DAD3350 DAD3351 X-axis 600 1,000 Y-axis 200 400 Z-axis 80 80

[mm/sec]

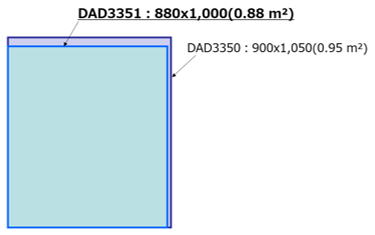

Small Footprint

- The footprint has been reduced by 10% compared to DAD3350.

Major Components of Model Change

Enhanced communication support and software support functions through installation of a new type of PC

- Supports SECS/GEM*1 (optional)

- Supports a communication network that enables batch control of multiple equipment

Productivity improvement through installation of a new type of NCS (Non-Contact Setup*2)

- Reduces time necessary to complete measurement of blade height against the processing table by 74%

- Improves processing quality through a stable cut depth for the workpiece by increasing measurement accuracy

Control performance improvement for X-, Y-, and Z-axis

- Possible to control the processing axis precisely through adoption of servo motors for each axis and high-speed communication support

- Improves processing quality by achieving a stable cut depth for the workpiece through high-precision height control

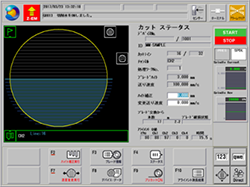

Innovation of Standard Software

- Adopts Windows 10 as OS

- Improves user-interface of the standard software

*1 Semiconductor industry communication standards (SECS: SEMI Equipment Communications Standard, GEM: Generic Model for Communication and Control of Manufacturing Equipment)

*2 Function that detects blade height by using a transmission sensor, without the blade contacting the chuck table upper surface

Semi-Automatic Dicing Saw Lineup

| Supported workpiece size | Φ150 mm | Φ200 mm | Φ300 mm | |||

|---|---|---|---|---|---|---|

| Dual spindle |

|

|

||||

| High precision |

|

|||||

| Single spindle |

Equipment width: 490 mm |

|

|

|

||

Upcoming Schedule

| December 2019 | DAD324, DAD3351, and DAD3651 will be exhibited at SEMICON Japan 2019 (December 11 – 13, Tokyo Big Site) |

|---|---|

| January 2020 | Sales release for DAD3351, DAD3361, and DAD3431 (Other semi-automatic dicing saws: Available for purchase) |

*DAD3350 and other existing models are also available for purchase.

Contact

Please feel free to contact us with any questions or inquiries.