The mechanical strength of low-K film used as insulating film for high-speed logic is low, and thus, there is the risk of film peeling when the normal blade dicing process is used. The low-K grooving process removes the wiring layer, including the low-K film, using laser grooving equipment.

Application

Laser grooving process

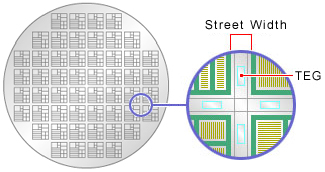

First, the DFL7161 rapidly makes two laser grooves in the dicing street - either "Pi Laser Grooving" or "Omega Laser Grooving"; then the wafer is blade-diced at standard speed. This application achieves excellent throughput yet greatly reduces or eliminates chipping, delamination and other cut-quality issues.

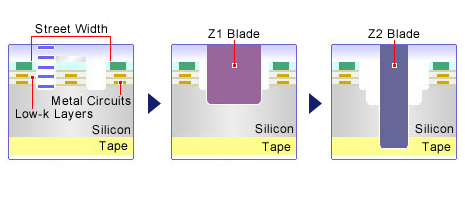

Pi (π) laser grooving(Step cut blade dicing)

Movie

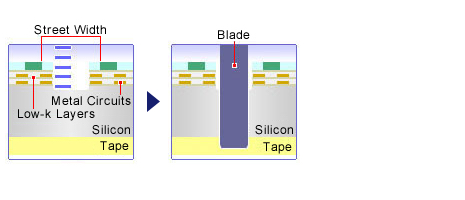

Omega (ω) laser grooving(One pass blade dicing)

Movie

Application Example

-

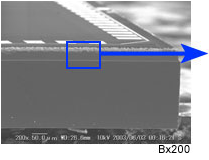

Cross sectional view of dicing street

Pi (π) laser grooving followed by step cut blade dicing.

-

Magnification of Low-k layer & metal circuits

Little or no chipping and delamination.

Equipment

Precision and Ease of Use

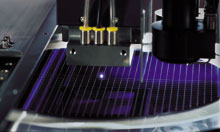

The DFL7161 (300 mm compatible) Fully Automatic Laser Saw utilizes short pulse laser technology to groove the streets of Low-k and Cu wafers with little or no heat damage. An LCD touch screen graphical user interface allows for excellent ease of operation.

Laser process

Laser

Cutting Quality

The DFL7161 focuses a short pulse UV laser on the surface of the wafer. Each pulse is absorbed by the Low-k material. After successive laser pulses, sufficient energy is absorbed to cause the Low-k material to vaporize. The vaporized material carries away the energy from the interaction, thereby minimizing heat transfer to the surrounding material.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details