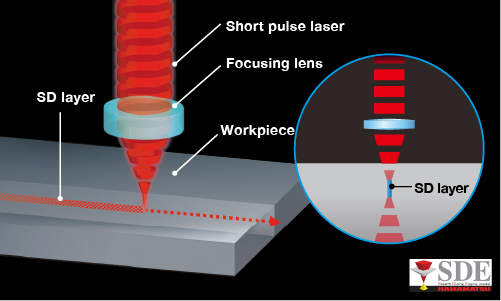

What is Stealth Dicing™ process?

"Stealth Dicing™ process" forms a modified layer in the workpiece by focusing a laser inside the workpiece, and then a tape expander is used to separate the die.

-

Before tape expansion

-

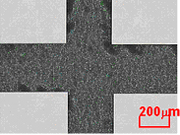

After tape expansion

DISCO is an alliance partner* of Hamamatsu Photonics, which owns the portfolio of patents for Stealth Dicing technology.

*System integrators who are business partners with comprehensive licensing for the portfolio of patents for Hamamatsu Stealth Dicing technology.

https://www.hamamatsu.com/jp/en/product/semiconductor-manufacturing-support-systems/stealth-dicing-technology/alliance-partners.html

Merits of Stealth Dicing™ Process

- Able to suppress cutting waste because it modifies an internal portion of the workpiece. Therefore, it is suitable for workpieces that are vulnerable to contamination.

- It is a dry process that does not require cleaning, therefore it is suitable to processes (such as MEMS) that are vulnerable to load.

- Greatly contributes to street reduction because the kerf width can be made narrow.

Examples

MEMS dicing

The profile of a MEMS die, such as one with a hollowed structure, or one that is already embedded with complicated minute elements, is generally not strong enough for cleaning water or the dicing load. Stealth dicing can be expected to result in high-quality processing of MEMS because it does not use water for processing or cleaning, and there is little or no damage to the die front or back surfaces.

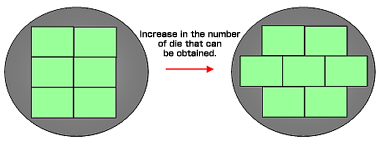

Street reduction

Stealth Dicing™ process is expected to increase the number of die that can be obtained from a wafer compared to normal dicing because it is possible to make the necessary street width (cut width) narrower. This is a particularly effective processing method for long shaped die, such as line sensors.

Comparison of the number of die that can be obtained from one wafer

The number of die obtained from one wafer increases by reducing the street width on a wafer with long-shaped dies.

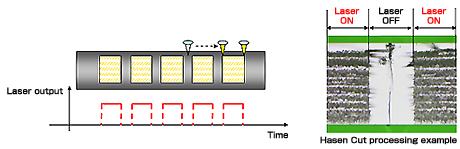

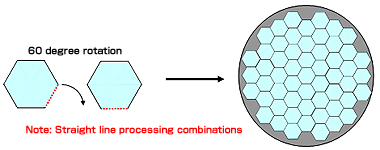

Hasen Cut

A Hasen Cut is a method that cuts while repetitively turning the laser ON/OFF at a set cycle during laser processing. It is possible to process various shapes depending on the ON/OFF setting.

Hasen Cut application example

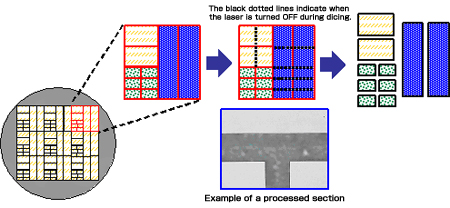

- Systematic complex die size wafer cut

By using the Hasen Cut, it is possible to process a wafer with combinations of irregular die shapes that could not be realized with the existing laser full cut processing or a blade dicer.

- Processing irregular shaped die

This cutting method can efficiently process workpieces like polygon shaped die, such as hexagons and octagons. Depending on the conditions, it is also be possible to process irregular shaped die.

- Die offset processing

By applying the Hasen Cut, the dicing street can also support intermittent die layout, as shown in the illustration below. This is effectively useful for large die sizes, high-priced wafers or long die, and enables increasing the number of die that can be obtained.

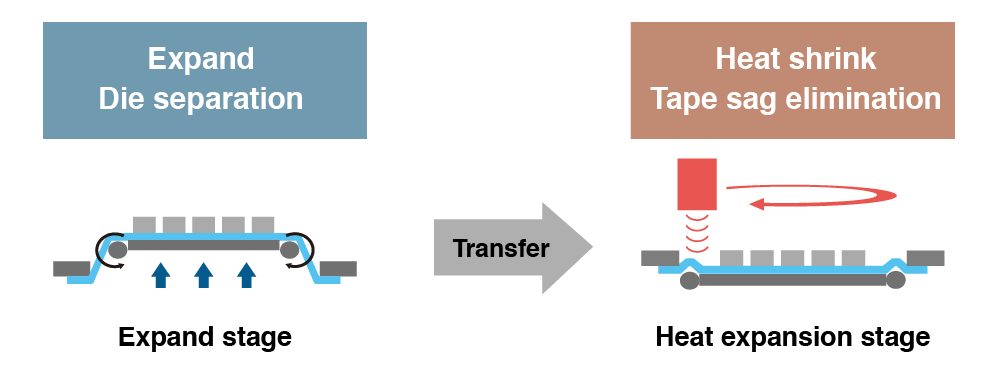

Die separation using die separator

Die separators separate wafers with SD layers into die through dicing tape expansion. After the SD process, the wafer is separated into die using tape expansion in the expansion stage. Then, tape outer sag is eliminated by shrinking the tape using temperatures higher than 200 deg. C (heat shrink) in the heat expansion stage. By doing so, it is possible to transfer wafers to the next process on the tape frame without re-mounting the tape.

Process handling equipment

Equipment models that support Stealth Dicing are equipped with an SD engine, which has a modularized laser and optical system developed by Hamamatsu Photonics for DISCO.

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details