DAG811Automatic Surface Grinder

An automatic grinder that has evolved to support a wide range of needs

- Φ200 mm

- 1 axis, 1 chuck table

Next-generation manual grinder that supports Φ8-inch workpieces

DAG811 is the next-generation model to DAG810, featuring a single-axis, single-chuck table configuration. It accommodates workpieces up to Φ8 inches (200 mm) in diameter, and supports Φ300 mm workpieces as an optional specification.

Supporting a wide range of needs

- Enhanced grinding accuracy and broader material compatibility

By optimizing the processing point layout and redesigning the axis structure, the grinding accuracy stability has been further improved. Additionally, by selecting a high-power spindle as an optional specification, the equipment can handle difficult-to-process materials. - Flexible grinding methods for diverse processing needs

DAG811 supports both in-feed grinding and creep-feed grinding methods. Automatic switching between the two modes is possible as an optional specification, eliminating the need for conversion work and enhancing operational efficiency and throughput.

Enhanced operability

Incorporating DISCO’s new design concept, the operation screen size has been enlarged from 10.4 inches to 15 inches, doubling the display area for improved visibility and usability.

Furthermore, the optional motorized fine-adjustment axis allows on-screen wafer shape correction.

Improved workability

During wheel replacement, the spindle can be raised above the water case, allowing operators to perform replacement without reaching inside the case.

This simplifies maintenance and prevents contamination of cleanroom wear.

Compact design

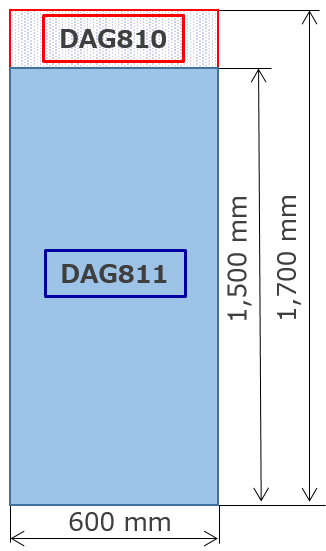

By reducing the equipment depth by 200 mm compared to the previous model, the footprint has been reduced by approximately 12 %, making DAG811 the first DISCO grinder with a floor area of less than 1 m2.

Specifications

| Specification | Unit | ||

|---|---|---|---|

| Supported workpiece size | - | Φ8 inches (Φ4, 5, 6, 8 inches when using a universal chuck table) |

|

| Grinding method | - | In-feed grinding or Creep-feed grinding | |

| Grinding wheels | - | Φ200 mm diamond wheel | |

| Spindle | Rated output | kW | 4.2 |

| Rated torque | N・m | 5.7 | |

| Rotation speed range | min‐1 | 1,000 - 7,000 (Rated speed:7,000) | |

| Equipment dimensions(W × D × H) | mm | 600 × 1,500 × 1,800 | |

| Equipment weight | kg | Approx.1,600 | |

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.

Product Lineup

| Machine type |

| Spindle |

| C/T |

| Machine dimentions(W × D × H) |

| Machine weight(kg) |

DAG811Automatic Surface Grinder

Contact

Please feel free to contact us with any questions or inquiries.