DMM9200Fully Automatic MUSUBI Wafer Mounter

Wafer mounter that achieves stable processing of ultra-thin wafers and compatible with MUSUBI

- Φ300 mm

- DBG

- SDBG

- Wafer Thinning

Next-generation wafer mounter that supports Φ300 mm wafers

DMM9200 automates the processes from frame mounting of wafers that have been thinned to 15 μm or below to protective tape peeling and is the successor to DFM2800. Cleaning functions within the equipment have been improved, making it possible to prevent wafer breakage due to particle entrapment.

Reduced equipment downtime

The time taken for tape replacement has been reduced by 85 % by optimizing the feed path of the dicing tape (compared to DISCO’s conventional equipment). In addition, further equipment downtime reduction is possible by installing optional mechanisms such as an automatic dicing tape changer and frame supply unit.

Can be used as part of MUSUBI

DMM9200 is compatible with MUSUBI, a cluster system that connects multiple equipment units. MUSUBI enables selection of an equipment combination that is suitable for the customer’s manufacturing process. As transfer within the equipment is automated, it is possible to achieve wafer breakage risk reduction and improved throughput.

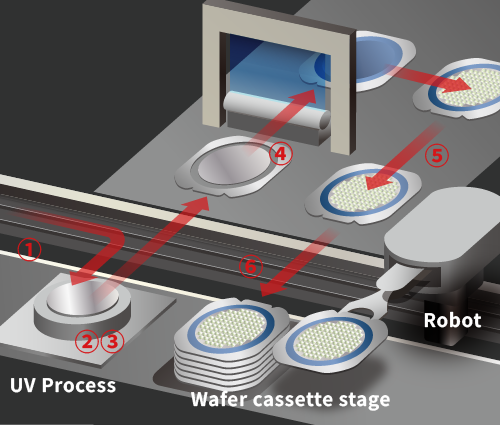

Workflow

- Workpiece is received from the grinder/polisher.

- UV irradiation is performed on the workpiece surface protective tape (when using UV tape).

- Workpiece is transferred to the inspection stage (optional).

- Workpiece with dicing tape attached is mounted on a tape frame.

- Surface protective tape is peeled.

- Workpiece is unloaded to the cassette.

Specifications

| Specifications | Unit | DMM9200 |

|---|---|---|

| Supported workpiece size | mm | Φ200 / Φ300 |

| Wafer mounting accuracy in the X/Y direction (frame mounting) | mm | ±0.5 or less |

| Wafer mounting accuracy in the θ direction (frame mounting) | degrees | ±0.5 or less |

| Dicing tape mounting accuracy in the X/Y direction | mm | ±1.0 or less |

| Equipment dimensions (W×D×H) | mm | 2,150 × 3,450 × 1,800 |

| Equipment weight | kg | Approx. 3,350 |

* Please read the standard specification sheet before using the equipment.

* Please note that items and specifications may be changed for improvement without prior notice.

Product Lineup

DMM9200Fully Automatic MUSUBI Wafer Mounter

Contact

Please feel free to contact us with any questions or inquiries.