MUSUBI

Solutions

MUSUBI is a flexible cluster system designed to connect multiple processing units, enabling efficient adaptation to a wide range of manufacturing processes. It automates wafer transfer between equipment, reducing the risk of wafer breakage and improving throughput. Additionally, a metrology unit can be installed, enabling wafer condition measurement at any point during the process.

Advantages of MUSUBI

Achieves flexible equipment configuration according to the manufacturing process

MUSUBI connects multiple units and different types of equipment to a shared transfer section, making it possible to achieve flexible equipment configurations as necessary for the customer’s manufacturing processes. In addition, equipment manufactured by companies other than DISCO can also be connected to MUSUBI as long as they are compatible.

Example: When DML7362, DMG8762, DME8061, and DMM9200 are connected

Achieves high throughput and high-quality processing through automated wafer transfer

MUSUBI uses robot-based automatic wafer transfer to prevent wafers from being idle between processes and to improve throughput across the entire line. Additionally, by reducing the frequency of manual operations such as equipment loading and recipe selection by operators, the system suppresses wafer breakage risk and ensures stable quality.

Enables wafer measurement during processing

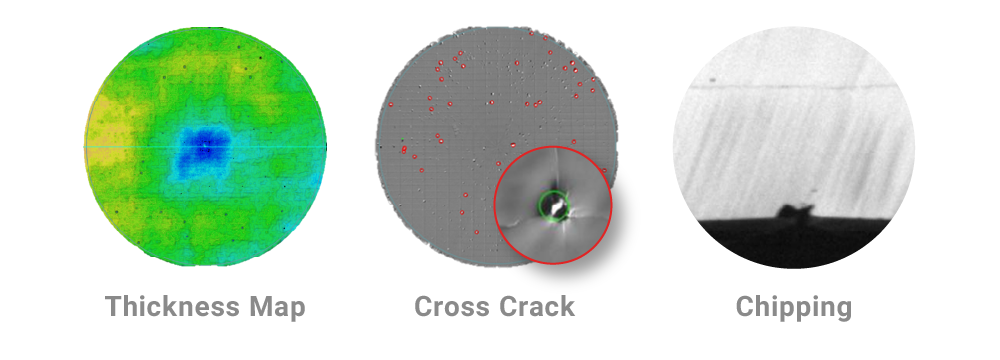

With MUSUBI’s built-in metrology unit, GI@dMETRO, wafer thickness, waviness, and image measurement can be performed at any timing during the process. Early detection of irregularities is possible, and the measurement results can be utilized for quality management.

Acquisition of Accreditation for Dimensional Calibration in Accordance with International Standard ISO/IEC17025:2017

Compatible Processing Equipment

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details