DME8061Fully Automatic MUSUBI Dry Etcher

A MUSUBI dry etcher that achieves improved die strength

- Φ300 mm

- DBG

- SDBG

- Wafer Thinning

- Stress Releaf

Achieves improved die strength by using plasma stress relief

DME8061 is a dry etcher that can achieve non-contact stress relief using plasma.

Improved die strength can be achieved by removing the damaged layer that remains after grinding.

Prevents metal contamination using plasma gettering

It is possible to switch the processing gas after performing stress relief so that the gettering process* can be performed consecutively.

Metal contamination of the device surface is suppressed by forming a gettering layer on the ground surface.

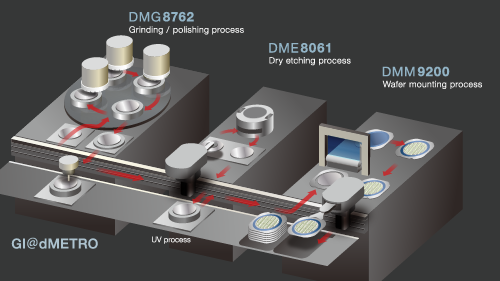

Can be used as part of MUSUBI

DME8061 is compatible with MUSUBI, a cluster system that connects multiple equipment units. MUSUBI enables selection of an equipment combination that is suitable for the customer’s manufacturing process. As transfer within the equipment is automated, it is possible to achieve wafer breakage risk reduction and improved throughput.

Example of process with equipment connected through MUSUBI_002:

DMG8762 (grinder/polisher) + DME8061 (dry etcher) + DMM9200 (wafer mounter)

By implementing the plasma stress relief and plasma gettering processes for the die surface using DME8061 after the SDBG® (Stealth Dicing Before Grinding) process, it is possible to achieve both improved die strength and a gettering effect.

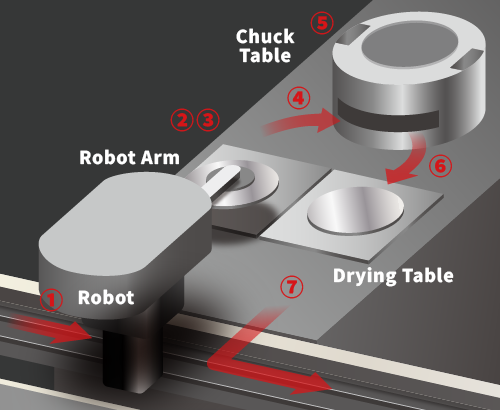

Workflow

- Workpiece is received from the grinder/polisher.

- Robot transfers the workpiece to the drying table.

- Workpiece is dried.

- Workpiece is transferred to the chuck table inside the chamber using the transfer arm.

- Plasma stress relief and gettering processes are performed.

- Workpiece is transferred to the positioning table using the transfer arm.

- Robot receives and transfers the workpiece to the mounter.

Specifications

| Specification | Unit | DME8061 | |

|---|---|---|---|

| Supported workpiece size | mm | Φ300 | |

| Processing gas | - | SF6, Ar | |

| Equipment dimensions (W×D×H) | mm | 1,400 × 2,200 × 1,800 | |

| Equipment weight | kg | Approx. 2,600 | |

* Customer must prepare a gas abatement system.

* Please read the standard specification sheet before using the equipment.

* Please note that items and specifications may be changed for improvement without prior notice.

Product Lineup

DME8061Fully Automatic MUSUBI Dry Etcher

Contact

Please feel free to contact us with any questions or inquiries.