DDS2020Fully Automatic Die Separator

A fully-automatic die separator that enables high-quality separation of hard materials

- Φ200 mm

- SDTT

Achieves improved wafer separation yield

DDS2020 achieves stable die separation of wafers where a modified layer has been created inside the wafer using the Stealth Dicing™ process. DDS2020 also supports separation following processes such as laser grooving and blade half-cut.

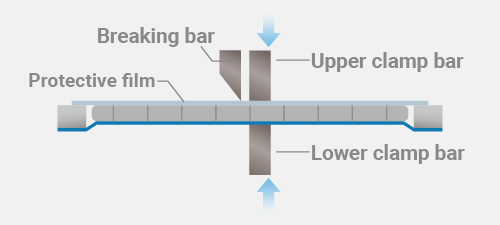

DDS2020 is equipped with a unique breaking mechanism where the wafer is secured by upper and lower clamp bars, and separation is performed by pushing down a breaking bar. Therefore, high-quality separation is possible for wafers that are difficult to separate through just tape expansion.

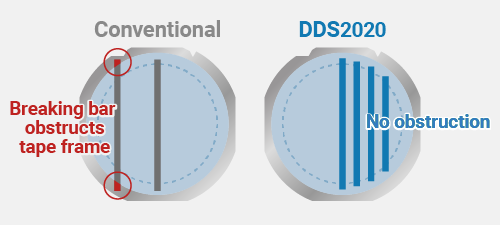

Tape frame remounting unnecessary

Conventionally, remounting to a Φ300 mm tape frame was necessary for Φ200 mm wafer breaking. However, DDS2020 enables separation of Φ200 mm wafers without needing to remount to a larger tape frame, as the upper and lower clamp bars and the breaking bar can operate without being obstructed by the frame.

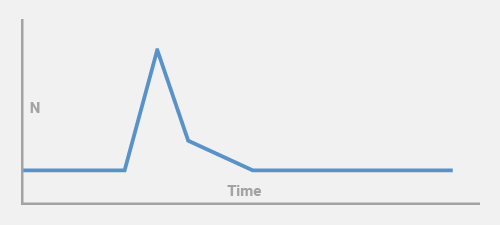

Load visualization during separation

By measuring the breaking bar load, unseparated die can be detected. Breaking is also retried for unseparated lines to ensure complete separation.

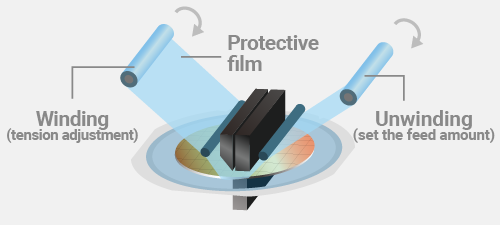

Automatic protective film feeder*

Automatic feeding of the surface protective film reduces operator workload.

*Option

Specifications

| Specifications | Unit | DDS2020 |

|---|---|---|

| Max. workpiece size | mm | Φ200 |

| Equipment dimensions (W×D×H) | mm | 1,250 × 1,037 × 1,800 (excluding protrusions and status light) |

| Equipment weight | kg | Approx. 800 |

* Please read the standard specification sheet before using the equipment.

* Please note that items and specifications may be changed for improvement without prior notice.

Product Lineup

DDS2020Fully Automatic Die Separator

Contact

Please feel free to contact us with any questions or inquiries.