TAIKO® Process

Solutions

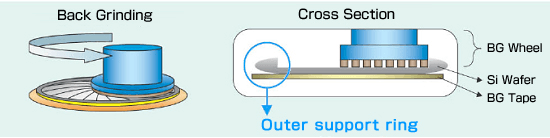

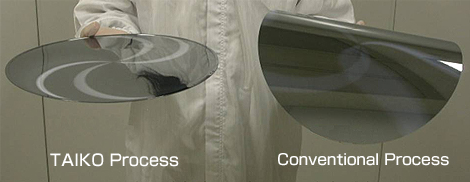

The TAIKO process is the name of a wafer back grinding process. This method is different to conventional back grinding. When grinding the wafer, the TAIKO process leaves an edge (approximately 3 mm) on the outer most circumference of the wafer and thin grinds only the inner circumference. By using this method, it lowers the risk of thin wafer handling and lowers warpage.

“TAIKO Process” merits

By leaving a frame on the outer circumference of the wafer

- Lowers wafer warpage

- Improves wafer strength

Improves the ease of wafer handling

Improves the ease of processing (through hole formation, bump distribution, etc) after thinning

Advantage of integrated structure* compare to a hard substrate

- When a high-temperature process (metallization, etc) is required after wafer thinning, out gas does not occur.

- Lower introduction of particles due to integrated structure and simple shape

*The wafer can maintain its structure (shape) without using a hard substrate.

-

Wafer hold based on hard substrate

-

TAIKO Wafer

Advantages of not putting a load on the outer circumference when grinding

- Easy to grind a wafer with a step on the outer circumference

- Zero edge chipping

-

Standard Process

-

TAIKO Process

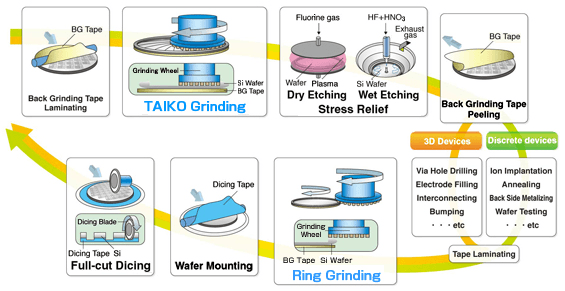

TAIKO Process Flow

Specification

-

DAG810(TAIKO Specification)

Automatic grinder

-

DTG8440

For Φ200 mm wafers

Fully Automatic TAIKO Grinder -

DTG8460

For Φ300 mm wafers

Fully Automatic TAIKO Grinder

Contact

Please feel free to contact us with any questions or inquiries.

-

Applications Support

A free-of-charge test cut is performed at an application lab to confirm whether achieving the customer's needs is possible.

Details -

Dicing and Grinding Service

It is effective in sample and prototype manufacturing during development or low-volume production. Designated engineers will provide support based on the desired leadtime and at reasonable cost.

Details