DFL7262Fully Automatic Laser Saw

A standard laser saw model with an ultrashort-pulse laser

- Φ300 mm

- Ablation

- DFL7262 is a fully automatic laser saw for Φ300 mm wafers.

- An ultrashort-pulse laser head and optical system can be installed.

- It automatically performs the entire series of processes, from HogoMax* coating, through dicing, to cleaning.

- By separating the HogoMax coating and cleaning sections, productivity can be improved.

*HogoMax:A water-soluble protective film that prevents laser processing particles from adhering to the wafer surface

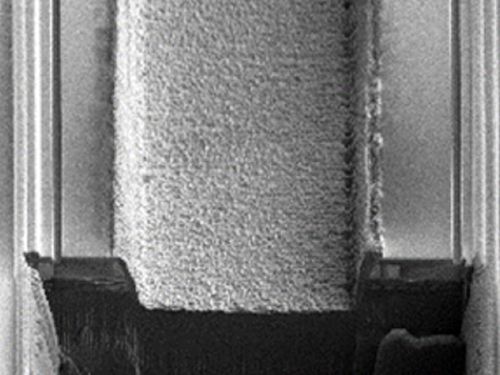

Grooving process for low-k wiring layer

Processing is possible while minimizing heat damage using the ultrashort-pulse laser

Low-k wiring layer grooving

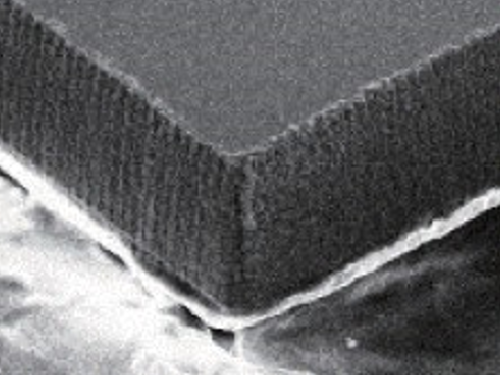

Full-cut processing of composite structures

Achieves high-quality processing of composite structures including Si wafers with DAF and Si/Mold

Si/DAF full-cut

Wafer transfer and tape frame transfer

Transfer method can be switched easily by performing replacement of some parts and size conversion

[Tape frame transfer]

Processing of wafers after grinding

[Wafer transfer]

Processing of wafers before grinding

Processing Examples

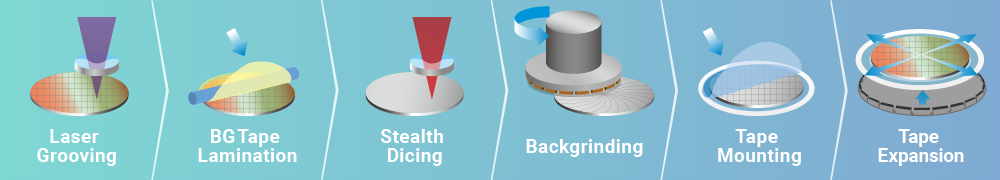

Wiring layer removal for logic devices (tape frame transfer)

Wiring layer removal for high bandwidth memory (HBM) devices (tape frame transfer)

Pattern and/or wiring layer removal for NAND/DRAM memory devices (wafer transfer)

Specifications

| Specifications | Unit | DFL7262 | |

|---|---|---|---|

| Max. workpiece size | mm | Φ300 | |

| X axis (chuck table) |

Cutting range | mm | 310 |

| Cutting speed range | mm/s | 1 to 1,000 | |

| Y axis (chuck table) |

Cutting range | mm | 310 |

| Index step | mm | 0.0001 | |

| Positioning accuracy | mm | 0.003 or smaller/310 (Single pitch error) 0.002 or smaller/5 |

|

| Z axis | Movement resolution | mm | 0.00002 |

| Repeatability accuracy | mm | 0.002 | |

| θ axis (Chuck table) |

Max. rotation angle | deg | 330 (standard) 380 (option) |

| Equipment dimensions (W×D×H) | mm | 1,560 × 1,680 × 1,800 | |

| Equipment weight | kg | Approx. 2,360 | |

* Please read the standard specification sheet before using the equipment.

* Please note that items and specifications may be changed for improvement without prior notice.

* HogoMax is a registered trademark of DISCO CORPORATION in Japan and other countries.

Product Lineup

DFL7262Fully Automatic Laser Saw

Contact

Please feel free to contact us with any questions or inquiries.